That high-pitched squealing coming from under your hood? Or maybe your power steering suddenly feels like you're wrestling an alligator? These could be signs of a problem brewing with a seemingly simple, yet incredibly vital component of your car: the serpentine belt.

A failing serpentine belt can quickly turn a smooth drive into a roadside headache. Imagine losing power steering while navigating a tight turn, or your air conditioning cutting out on a scorching summer day. Ignoring the warning signs can lead to more serious problems, potentially leaving you stranded and facing costly repairs.

This guide is all about the serpentine belt. We'll cover the common symptoms of a bad or loose serpentine belt, walk you through the replacement process (if you're the DIY type), and explain why this unassuming belt is so crucial to your vehicle's operation. We will explore the causes and consequences of a worn-out serpentine belt, as well as the necessary steps to address the issue and prevent future problems.

In this comprehensive guide, we'll delve into the telltale signs of a failing serpentine belt, such as squealing noises, visible cracks, and accessory malfunctions. We'll explore the step-by-step process of replacing the belt, empowering you to potentially tackle the job yourself. Additionally, we'll highlight the critical role of the serpentine belt in powering essential vehicle components like the alternator, power steering pump, and air conditioning compressor. Get ready to understand the ins and outs of this vital engine component.

Recognizing the Squeal: Common Serpentine Belt Symptoms

I remember driving my old pickup truck, "Betsy," back from a camping trip. About halfway home, a terrible squealing noise started. At first, I thought it was the brakes, but it persisted even when I wasn't braking. Then the steering got really heavy, and I realized something was seriously wrong. Turns out, Betsy's serpentine belt was cracked and slipping, causing the power steering pump to fail intermittently. That was a memorable (and stressful) learning experience!

The squealing noise is often the first sign that something is amiss. This occurs when the belt loses its grip on the pulleys it drives, usually due to wear, age, or contamination from oil or coolant. Think of it like a slipping rubber band – it just can't maintain a solid hold. Beyond the noise, you might notice a decrease in the performance of your car's accessories. A weak alternator, caused by a slipping belt, can lead to dimming headlights or difficulty starting the engine. Similarly, the air conditioning might blow warm air, or the power steering could feel stiff and unresponsive. Visually, inspect the belt itself. Look for cracks, fraying, missing chunks, or a glazed, shiny appearance. Any of these signs indicate that the belt is nearing the end of its life and needs replacement. Remember, the serpentine belt is a critical component, and neglecting these warning signs can lead to further damage and more expensive repairs down the road. If you hear squealing noises, notice performance problems, or see visible wear on the belt, it's time to take action.

What Exactly Isa Serpentine Belt?

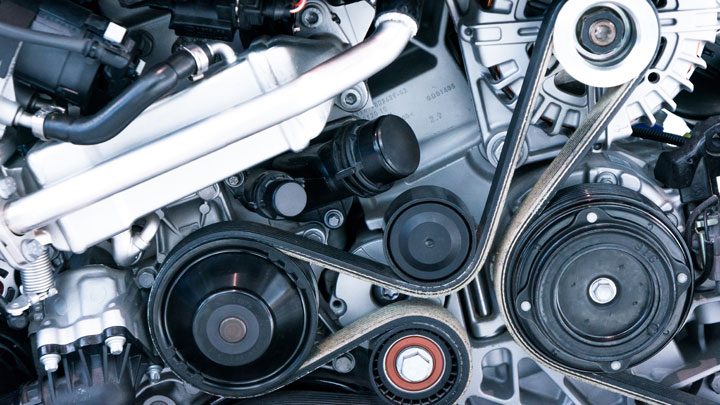

The serpentine belt, sometimes called the accessory drive belt, is a single, long belt that snakes around various pulleys connected to your engine. Its primary job is to transfer rotational power from the engine's crankshaft to several essential accessories. These accessories typically include the alternator (which charges the battery), the power steering pump (which provides power assist for steering), the air conditioning compressor (which cools the cabin), and sometimes the water pump (which circulates coolant to regulate engine temperature).

Think of the serpentine belt as the conductor of an orchestra, coordinating the performance of different instruments. Without it, these vital accessories wouldn't function, leading to a host of problems. The belt is made of a durable rubber compound, often reinforced with fibers, to withstand the constant tension and heat generated by the engine. Over time, however, the rubber deteriorates, causing the belt to crack, fray, and lose its grip. A loose belt can slip on the pulleys, reducing the efficiency of the accessories. A broken belt, on the other hand, will completely shut down these systems, potentially leaving you stranded. The tension on the serpentine belt is maintained by a tensioner pulley, which automatically adjusts to keep the belt properly tightened. A failing tensioner can also contribute to belt slippage and premature wear. Regular inspection and timely replacement of the serpentine belt are crucial for maintaining the reliable operation of your vehicle. Don't underestimate the importance of this seemingly simple component – it's the unsung hero that keeps your car running smoothly.

A Brief History and the Myth of the "Fan Belt"

Interestingly, the term "fan belt" is often mistakenly used interchangeably with "serpentine belt," but this is a relic of older car designs. Back in the day, vehicles used separate belts, one of which directly powered the engine's cooling fan. As automotive technology advanced, the single serpentine belt replaced multiple individual belts, streamlining the engine compartment and improving efficiency.

The history of the serpentine belt is closely tied to the evolution of automotive accessory systems. Early cars often relied on direct mechanical linkages to power accessories, but these systems were inefficient and cumbersome. As demand for features like power steering and air conditioning grew, engineers developed belt-driven systems to provide the necessary power. The transition to a single, multi-accessory belt was a significant step forward, simplifying maintenance and reducing the number of components. The myth of the "fan belt" persists because many people still associate belts with the cooling system, even though modern cars rarely use a separate belt for the fan. In fact, in many modern vehicles, the cooling fan is electric and operates independently of the serpentine belt. Understanding this historical context helps to appreciate the role of the serpentine belt in modern vehicles. It's a testament to how automotive technology has evolved to improve performance, reliability, and ease of maintenance. While the "fan belt" may be a term from the past, the serpentine belt remains a vital component of today's cars.

The Hidden Secret: Serpentine Belt Tension is Key

One of the most overlooked aspects of serpentine belt maintenance is proper tension. Too loose, and the belt will slip, leading to the symptoms we've already discussed. Too tight, and it can put undue stress on the bearings of the accessories, causing them to fail prematurely. The tensioner pulley plays a crucial role in maintaining the correct tension, but tensioners themselves can wear out over time.

The hidden secret lies in understanding how the tensioner works and how to check its condition. A typical tensioner uses a spring-loaded arm to automatically adjust the belt tension. Over time, the spring can weaken, reducing the tensioning force. The pulley itself can also become worn or seized, hindering its ability to maintain proper tension. When inspecting the serpentine belt, also examine the tensioner. Look for signs of excessive movement, rattling noises, or a worn pulley. A simple test is to try to move the tensioner arm by hand. If it moves too easily or feels loose, it's likely time to replace the tensioner. Maintaining the correct belt tension is not just about preventing slippage; it's also about protecting the longevity of your car's accessories. A properly tensioned belt ensures that the accessories operate efficiently and without excessive strain. So, when you're checking your serpentine belt, don't forget to pay attention to the tensioner – it's the key to unlocking the full potential of your accessory drive system. Ignoring the tensioner can lead to premature failure of the serpentine belt and other components.

Recommendations: When Should You Replace Your Serpentine Belt?

As a general rule of thumb, it's a good idea to replace your serpentine belt every 60,000 to 100,000 miles, or as recommended in your vehicle's owner's manual. However, this is just a guideline. Factors like driving conditions, climate, and the quality of the belt can affect its lifespan. Regular visual inspections are crucial to catch potential problems early.

The manufacturer's recommendation is always the best starting point for determining the replacement interval. However, it's important to consider your specific driving conditions. If you frequently drive in hot or dusty environments, the belt may wear out faster. Similarly, if you often tow heavy loads or engage in aggressive driving, the increased stress on the belt can shorten its lifespan. A visual inspection should be performed at every oil change or at least twice a year. Look for cracks, fraying, glazing, or any other signs of wear. If you notice any of these symptoms, it's time to replace the belt, regardless of the mileage. Choosing a high-quality replacement belt is also important. Opt for a belt from a reputable manufacturer that meets or exceeds the original equipment specifications. While a cheaper belt may save you money in the short term, it's likely to wear out faster and could potentially damage your accessories. Replacing the serpentine belt is a relatively inexpensive maintenance task that can prevent costly breakdowns. Don't wait until the belt breaks – be proactive and replace it before it causes problems. Regular inspections and timely replacements are key to maintaining the reliability of your vehicle.

Understanding Belt Material and Construction

Serpentine belts aren't just simple rubber bands. They're engineered with specific materials and construction techniques to withstand the harsh conditions under the hood. Most serpentine belts are made from a blend of synthetic rubber compounds, such as EPDM (ethylene propylene diene monomer) or neoprene. These materials offer excellent resistance to heat, oil, and abrasion.

The belts are reinforced with fibers, such as polyester or aramid, to provide strength and prevent stretching. The construction of the belt also plays a crucial role in its performance. Some belts feature a molded cog design, which allows them to bend more easily around tight pulleys and reduces heat buildup. Others have a multi-ribbed design, which increases the surface area in contact with the pulleys and improves grip. Understanding the different materials and construction techniques can help you choose the right belt for your vehicle. When selecting a replacement belt, consider the specific requirements of your car and the recommendations of the manufacturer. Opting for a belt that is designed for heavy-duty use or extreme conditions can be a good investment, especially if you frequently drive in challenging environments. The material of the belt is crucial to its ability to withstand the environment it operates in, therefore it is crucial to understand what type of material belt you are choosing.

Essential Tips for Serpentine Belt Replacement

If you're comfortable working on your car, replacing a serpentine belt is a task you can often tackle yourself. Here are a few essential tips:

First, always consult your vehicle's repair manual for specific instructions and torque specifications. Each car is different, and the belt routing and tensioner location can vary significantly. Before removing the old belt, make a diagram or take a photo of its routing. This will be invaluable when installing the new belt. Use the correct tools, including a serpentine belt tool, to release the tension on the tensioner pulley. Avoid using makeshift tools, as this can damage the tensioner or other components. When installing the new belt, make sure it is properly seated in all the pulleys. Double-check the routing against your diagram or photo. Once the belt is installed, start the engine and listen for any unusual noises. Check the belt tension after a few minutes of running. If the belt is too loose or too tight, adjust the tensioner accordingly. Remember safety first. Disconnect the negative battery cable before working on the serpentine belt to prevent accidental starts. By following these tips, you can successfully replace your serpentine belt and save yourself some money on labor costs. However, if you're not comfortable working on your car, it's always best to take it to a qualified mechanic.

Understanding Serpentine Belt Routing Diagrams

Serpentine belt routing diagrams are like treasure maps for your engine. They show the exact path the belt takes around all the pulleys. Without a clear diagram, you might end up routing the belt incorrectly, leading to accessory malfunctions or even belt damage. These diagrams are usually found in your vehicle's repair manual, but you can also often find them online or on a sticker under the hood.

If you can't find a diagram, don't guess! Take a photo of the existing belt routing before you remove it. The diagram will illustrate the proper alignment of the belt in relation to each pulley, ensuring that it is installed correctly. Following the correct routing is crucial for the proper operation of the accessories. An incorrectly routed belt can slip on the pulleys, reducing the efficiency of the alternator, power steering pump, and air conditioning compressor. It can also cause the belt to wear out prematurely or even break. Some diagrams also include information on the direction of rotation for each pulley, which is important for ensuring that the accessories are turning in the correct direction. A properly followed routing diagrams ensures that the accessories operate efficiently and without excessive strain. It's a simple step that can save you a lot of headaches down the road. If you're unsure about the routing, consult a qualified mechanic for assistance. Incorrect routing can lead to expensive repairs, so it's always best to be safe.

Fun Facts About Serpentine Belts

Did you know that the length of a serpentine belt can vary significantly depending on the vehicle? Some belts are only a few feet long, while others can be over ten feet! The length is determined by the number of accessories the belt drives and the layout of the engine compartment.

Another fun fact is that the serpentine belt is constantly flexing and bending as it travels around the pulleys. This constant flexing generates heat, which is why the belt is made of heat-resistant materials. Some high-performance serpentine belts are even designed with special cooling features to dissipate heat more effectively. The serpentine belt is a critical component of the vehicle's accessory drive system. Another surprising fact is that the serpentine belt is responsible for powering some of the most essential functions of your car, like the alternator, power steering pump, and air conditioning compressor. Without the serpentine belt, these functions wouldn't work, making driving much less enjoyable and potentially dangerous. The serpentine belt is constantly under stress, it undergoes constant flexing, bending, and exposure to heat and oil. This is why it's important to regularly inspect the belt for signs of wear and tear. A worn or damaged belt can fail unexpectedly, leaving you stranded on the side of the road. Replacing the serpentine belt is a relatively inexpensive maintenance task that can prevent costly breakdowns. So, next time you're under the hood of your car, take a moment to appreciate the humble serpentine belt – it's a hardworking component that plays a crucial role in keeping your car running smoothly.

How to Diagnose a Serpentine Belt Issue

Diagnosing a serpentine belt issue involves a combination of visual inspection and listening for unusual noises. Start by visually inspecting the belt for cracks, fraying, missing chunks, or a glazed appearance. Also, check the tensioner pulley for signs of wear or damage.

If you hear a squealing noise, try to determine where it's coming from. If the noise is consistent and increases with engine speed, it's likely coming from the serpentine belt. You can also try spraying a small amount of water on the belt while the engine is running. If the squealing stops temporarily, it confirms that the belt is the source of the noise. If the belt looks good but the squealing persists, the problem may be with one of the accessories that the belt drives. Check the pulleys for signs of wear or damage, and listen for unusual noises coming from the alternator, power steering pump, or air conditioning compressor. Another diagnostic tool is a belt tension gauge, which can be used to measure the tension of the belt. If the tension is too low, the belt may be slipping. Remember that diagnosing serpentine belt issues can be tricky. A process of elimination may be required. If you're not comfortable performing these tests, it's always best to take your car to a qualified mechanic. A professional can accurately diagnose the problem and recommend the appropriate repairs.

What Happens If You Ignore a Bad Serpentine Belt?

Ignoring a bad serpentine belt can have serious consequences. A slipping belt can lead to reduced performance of the alternator, power steering pump, and air conditioning compressor. This can result in dimming headlights, difficult steering, and poor cooling performance.

More importantly, a broken serpentine belt can completely disable these systems, leaving you stranded. A broken belt can also damage other components in the engine compartment. If the belt snaps, it can whip around and potentially damage other belts, hoses, or even the engine itself. In some cases, a broken serpentine belt can cause the engine to overheat, especially if the water pump is driven by the same belt. Overheating can lead to serious engine damage, requiring expensive repairs. Ignoring a bad serpentine belt is simply not worth the risk. Regular inspections and timely replacements are crucial for preventing these problems. A new serpentine belt is much cheaper than the potential cost of repairs resulting from a broken belt. Don't wait until it's too late – take care of your serpentine belt and keep your car running smoothly. Proactive maintenance is the key to avoiding costly breakdowns and ensuring the reliability of your vehicle.

Listicle: 5 Signs Your Serpentine Belt Needs Replacing

1. Squealing Noise: A high-pitched squealing noise coming from under the hood is often the first sign of a slipping serpentine belt.

2. Visible Cracks or Fraying: Inspect the belt for cracks, fraying, or missing chunks. Any of these signs indicate that the belt is nearing the end of its life.

3. Dimming Headlights: A weak alternator, caused by a slipping belt, can lead to dimming headlights, especially at night.

4. Stiff Steering: A slipping belt can reduce the performance of the power steering pump, making steering feel stiff and unresponsive.

5. Poor Air Conditioning Performance: A slipping belt can also affect the performance of the air conditioning compressor, resulting in warm air blowing from the vents.

These are the common sign that indicate that the belt is getting old, therefore this would mean that you must get ready to replace it. Failure to replace a failing serpentine belt can have serious consequences. If the belt breaks, it can leave you stranded on the side of the road. An unnoticed problem can cause damage to other components in the engine compartment. Overtime the signs will become more obvious, but it's important to check for signs often, so you can catch it as soon as possible.

Question and Answer Section

Q: How often should I replace my serpentine belt?

A: Most manufacturers recommend replacing the serpentine belt every 60,000 to 100,000 miles, or as specified in your vehicle's owner's manual. However, regular visual inspections are crucial to catch potential problems early.

Q: Can I replace the serpentine belt myself?

A: If you're comfortable working on your car and have the necessary tools, replacing the serpentine belt is a task you can often tackle yourself. However, always consult your vehicle's repair manual for specific instructions and torque specifications.

Q: What are the symptoms of a bad serpentine belt tensioner?

A: Symptoms of a bad serpentine belt tensioner include excessive belt movement, rattling noises, and a worn or seized pulley. The tensioner may also feel loose or move too easily when you try to adjust it by hand.

Q: What happens if my serpentine belt breaks while I'm driving?

A: If your serpentine belt breaks while you're driving, you'll likely lose power steering, air conditioning, and possibly alternator function. This can make steering difficult and may lead to the engine overheating. Pull over to a safe location as soon as possible and call for assistance.

Conclusion of Bad or Loose Serpentine Belt: Symptoms and Replacement

The serpentine belt is a small but mighty component that plays a vital role in keeping your car running smoothly. Recognizing the symptoms of a bad or loose serpentine belt, understanding the replacement process, and performing regular maintenance can prevent costly breakdowns and ensure the reliability of your vehicle. Don't wait until it's too late – be proactive and take care of your serpentine belt.