That high-pitched squealing sound coming from under your hood? It's not a happy engine; it's likely a cry for help! Ignoring it could lead to a roadside breakdown and a hefty repair bill. One of the most common culprits behind this automotive distress call is a failing or loose serpentine belt.

A malfunctioning serpentine belt can cause a domino effect of problems. Imagine your power steering going out while you're navigating a tight turn, or your air conditioning failing on a sweltering summer day. The alternator's ability to charge your battery diminishes, resulting in starting problems or a total electrical failure. These scenarios highlight the significance of a healthy serpentine belt for a smooth and safe driving experience.

This article will serve as your guide to identifying the symptoms of a bad or loose serpentine belt, understanding its function, and learning when and how to replace it. We'll delve into the common warning signs, explore the belt's crucial role in your vehicle's operation, and provide step-by-step instructions for replacement, empowering you to take proactive measures to keep your car running smoothly.

We'll cover the symptoms of a failing serpentine belt, such as squealing noises, visible cracks and damage, and issues with power steering, air conditioning, and battery charging. We'll also discuss the belt's function, replacement process, and preventative measures to extend its lifespan. We will also discuss history and myth of this topic.

Symptoms of a Bad or Loose Serpentine Belt

Recognizing the signs of a failing serpentine belt is crucial for preventing more significant and costly repairs. I remember driving home one evening when I heard a faint squealing noise that grew louder as I accelerated. At first, I dismissed it, thinking it was just a temporary issue. However, the noise persisted, and soon after, my power steering became noticeably weaker. It was difficult to turn the wheel, especially at low speeds. That's when I knew something was seriously wrong, and the serpentine belt was the prime suspect. This personal experience highlights the importance of not ignoring unusual noises or changes in your car's performance.

A bad or loose serpentine belt can manifest in several ways. The most common symptom is a high-pitched squealing or chirping sound coming from the engine, especially when the engine is first started or when accelerating. This noise is often caused by the belt slipping on the pulleys due to wear, looseness, or contamination with oil or coolant. Another visible sign is cracks, fraying, or chunks missing from the belt. Inspect the belt regularly for these types of damage. If you see any of these issues, it's time for a replacement. Performance issues can also indicate a problem, such as weakened or non-functional power steering, a non-cooling air conditioner, or an engine overheating due to a failing water pump. A dashboard warning light, like the battery light, may also illuminate, indicating a charging issue due to the alternator not being driven properly.

Catching these symptoms early can save you from more serious problems, like a complete breakdown or damage to other components. Regular inspections and prompt replacements are the keys to a healthy and reliable vehicle.

What is a Serpentine Belt?

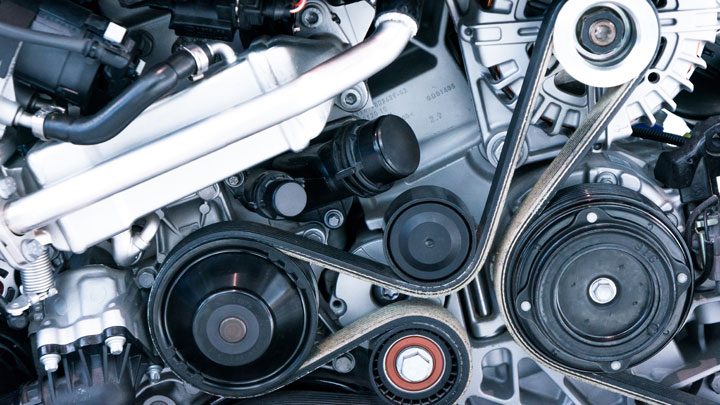

The serpentine belt is a long, winding belt that plays a vital role in powering several essential components of your vehicle. It's called a "serpentine" belt because it snakes around multiple pulleys, driving various accessories. Understanding its function is key to appreciating its importance and the potential consequences of its failure.

The serpentine belt is typically made of a durable rubber composite and is driven by the engine's crankshaft. It transfers power from the crankshaft to accessories such as the alternator, which charges the battery; the power steering pump, which assists with steering; the air conditioning compressor, which cools the cabin; and sometimes the water pump, which circulates coolant to regulate engine temperature. Without a properly functioning serpentine belt, these components cannot operate efficiently or at all. For instance, if the belt breaks or slips, the alternator will not charge the battery, leading to a dead battery and a stalled vehicle. The power steering will become difficult, making the car hard to maneuver, and the air conditioning will stop working, leaving you uncomfortable in hot weather.

The serpentine belt is a critical component that keeps your car running smoothly and comfortably. Regular maintenance and timely replacements are essential to ensure its proper function and avoid potentially dangerous or inconvenient situations. Neglecting the serpentine belt can lead to a chain reaction of failures that can leave you stranded on the side of the road.

History and Myths About Serpentine Belts

The serpentine belt, while a relatively modern invention in automotive technology, has an interesting history. Before the serpentine belt, vehicles used multiple V-belts to drive individual accessories. This system was less efficient, more complex, and required more maintenance due to the individual adjustment and replacement of each belt. The serpentine belt emerged in the late 20th century as a simpler, more efficient solution. It allowed manufacturers to drive all the accessories with a single belt, reducing the number of components, simplifying the engine design, and improving reliability.

One common myth about serpentine belts is that they last forever or require very little maintenance. While modern serpentine belts are more durable than their predecessors, they still wear out over time due to constant flexing, heat exposure, and environmental factors. Another myth is that a squealing belt can be easily fixed with belt dressing or other temporary solutions. While these products might temporarily quiet the noise, they don't address the underlying problem, such as wear, cracks, or misalignment. In fact, some belt dressings can actually accelerate belt deterioration by making the belt more prone to slippage.

It's essential to dispel these myths and understand that serpentine belts require regular inspection and periodic replacement. Ignoring the belt can lead to unexpected failures and more costly repairs. Proper maintenance, including checking the belt for wear and tear and replacing it at recommended intervals, is the key to preventing breakdowns and ensuring the reliable operation of your vehicle.

Hidden Secrets of the Serpentine Belt

The serpentine belt, seemingly a simple rubber component, holds a few hidden secrets that are worth knowing. One secret lies in its composition. Modern serpentine belts are typically made of a sophisticated blend of rubber compounds, reinforced with strong fibers like aramid or polyester. These materials are designed to withstand extreme temperatures, constant flexing, and exposure to oil and other contaminants. The specific blend of materials and the belt's construction play a significant role in its durability and lifespan.

Another hidden secret is the importance of proper tension. The serpentine belt relies on precise tension to maintain optimal contact with the pulleys and prevent slippage. Too little tension can cause the belt to slip, leading to squealing noises, reduced accessory performance, and accelerated wear. Too much tension can overload the belt and the accessory bearings, shortening their lifespan. Most modern vehicles use automatic tensioners that maintain the correct tension automatically, but it's still essential to inspect the tensioner periodically for proper function.

A final secret is the role of pulley alignment. Even with a properly tensioned belt, misaligned pulleys can cause premature wear and failure. Misalignment can occur due to bent brackets, damaged pulleys, or improperly installed accessories. When replacing a serpentine belt, it's always a good idea to check the pulley alignment to ensure that the new belt will last as long as possible. Using a laser alignment tool can help identify and correct misalignment issues. These hidden secrets reveal that the serpentine belt is more than just a simple rubber strap; it's a precision component that requires careful attention and maintenance.

Recommendations for Serpentine Belt Maintenance

To ensure the longevity and reliability of your serpentine belt, it's important to follow a few simple maintenance recommendations. Regular inspections are key. At least twice a year, or every time you change your oil, inspect the belt for signs of wear, such as cracks, fraying, or missing chunks. Pay close attention to the ribs of the belt, as these are most susceptible to damage. If you notice any of these signs, it's time to replace the belt.

Another recommendation is to check the belt tension and the condition of the tensioner. Most modern vehicles have automatic tensioners that maintain the correct belt tension, but these can fail over time. If the tensioner is loose or if you notice excessive belt vibration, replace the tensioner along with the belt. Also, keep the belt clean and free from oil or other contaminants. Oil can cause the belt to slip and deteriorate prematurely. If you notice oil on the belt, identify and fix the source of the leak.

Finally, follow the manufacturer's recommended replacement interval. Most manufacturers recommend replacing the serpentine belt every 60,000 to 100,000 miles, but this can vary depending on the vehicle and driving conditions. Even if the belt looks okay, it's best to replace it at the recommended interval to avoid unexpected failures. By following these simple maintenance recommendations, you can extend the life of your serpentine belt and ensure the reliable operation of your vehicle.

Serpentine Belt Replacement Procedure

Replacing a serpentine belt can be a relatively straightforward DIY project, but it's important to follow the correct procedure and take necessary safety precautions. First, gather the necessary tools, including a new serpentine belt, a socket set, a wrench, and a belt routing diagram (usually found on a sticker under the hood). Disconnect the negative battery cable to prevent any electrical accidents.

Locate the serpentine belt tensioner. This is usually a spring-loaded pulley that applies tension to the belt. Use a socket or wrench to rotate the tensioner, relieving the tension on the belt. While holding the tensioner in the released position, carefully remove the old belt from the pulleys. Take note of the belt routing before removing it, or refer to the belt routing diagram. With the old belt removed, inspect the pulleys for any signs of damage or wear. Replace any damaged pulleys before installing the new belt.

Install the new belt by routing it around the pulleys according to the diagram. Make sure the belt is properly seated in the grooves of each pulley. Once the belt is in place, release the tensioner, allowing it to apply tension to the new belt. Double-check that the belt is correctly routed and seated on all the pulleys. Reconnect the negative battery cable and start the engine. Listen for any unusual noises and inspect the belt for proper tracking. If everything looks and sounds good, you've successfully replaced your serpentine belt. Remember, if you're not comfortable performing this task yourself, it's always best to consult a qualified mechanic.

Tips for Extending Serpentine Belt Life

Extending the life of your serpentine belt involves a few simple but effective strategies. One crucial tip is to avoid harsh driving habits. Excessive acceleration and high engine speeds can put extra strain on the belt, leading to premature wear. Smooth, moderate driving can significantly extend the belt's lifespan. Another tip is to keep the engine bay clean and free from oil and other contaminants. Oil can cause the belt to slip and deteriorate the rubber. Regularly inspect the engine for leaks and address them promptly.

Also, avoid using belt dressing or other temporary solutions. While these products might temporarily quiet a noisy belt, they don't address the underlying problem and can actually accelerate belt wear. Instead, focus on proper maintenance and timely replacements. Check the belt tension regularly. If the belt is too loose, it will slip and wear out quickly. If it's too tight, it can overload the belt and the accessory bearings. Most modern vehicles have automatic tensioners, but it's still a good idea to inspect them periodically.

Finally, use quality replacement belts. Cheaper belts might seem like a good deal, but they are often made from inferior materials and won't last as long as a high-quality belt from a reputable brand. Investing in a good belt is worth it in the long run. By following these tips, you can significantly extend the life of your serpentine belt and save money on repairs.

Choosing the Right Replacement Serpentine Belt

Selecting the correct replacement serpentine belt is crucial for ensuring proper fit and performance. Not all belts are created equal, and using the wrong one can lead to problems. First, consult your vehicle's owner's manual or a reliable parts catalog to determine the correct belt size and type for your specific make and model. Serpentine belts are identified by their length, width, and number of ribs. Using a belt that is too long or too short can cause it to slip or not fit properly.

When choosing a replacement belt, opt for a reputable brand known for quality and durability. Avoid cheap, generic belts, as they are often made from inferior materials and won't last as long. Look for belts made from high-quality rubber compounds reinforced with strong fibers like aramid or polyester. These belts are designed to withstand extreme temperatures and constant flexing.

Consider the driving conditions and the vehicle's application. If you frequently drive in harsh conditions or use your vehicle for heavy-duty applications, you might want to choose a heavy-duty belt designed for increased durability. These belts often have additional reinforcement and are designed to withstand higher temperatures and loads. Finally, pay attention to the belt's construction. Some belts have a molded cog design, which helps reduce heat and improve flexibility. Others have a ribbed design that enhances grip and reduces slippage. Choosing the right replacement serpentine belt is an investment in your vehicle's reliability and performance.

Fun Facts About Serpentine Belts

Serpentine belts, while seemingly mundane, have some interesting and fun facts associated with them. Did you know that the serpentine belt is sometimes referred to as an "accessory drive belt" because it drives many of the vehicle's essential accessories? These accessories include the alternator, power steering pump, air conditioning compressor, and water pump. Without the serpentine belt, these components wouldn't function, making the car undrivable.

Another fun fact is that the serpentine belt can travel at speeds of up to 100 miles per hour when the engine is running at high RPMs. That's why it's important to keep the belt in good condition and replace it at recommended intervals. A broken serpentine belt can cause a lot of damage and leave you stranded. Serpentine belts are made from a variety of materials, including rubber, neoprene, and EPDM (ethylene propylene diene monomer). EPDM is a synthetic rubber that is resistant to heat, oil, and ozone, making it a popular choice for serpentine belts.

The serpentine belt is a relatively modern invention. Before the serpentine belt, vehicles used multiple V-belts to drive individual accessories. The serpentine belt simplified the design and reduced the number of components needed. Finally, serpentine belts are recyclable. When you replace your serpentine belt, you can take the old one to a recycling center. The rubber can be recycled and used to make other products, such as playground surfaces and flooring. These fun facts highlight the importance and ingenuity of the serpentine belt, a small but crucial component of modern vehicles.

How to Inspect a Serpentine Belt

Regularly inspecting your serpentine belt is a crucial part of vehicle maintenance. Fortunately, it's a relatively simple process that you can do yourself. First, park your car on a level surface and turn off the engine. Open the hood and locate the serpentine belt. It's usually located at the front of the engine and winds around several pulleys. Use a flashlight to get a good view of the belt.

Look for any signs of wear, such as cracks, fraying, or missing chunks. Cracks are the most common sign of wear and can indicate that the belt is about to fail. Pay close attention to the ribs of the belt, as these are most susceptible to damage. Also, check the edges of the belt for fraying. Fraying can be caused by misalignment or excessive wear. If you see any missing chunks of rubber, it's definitely time to replace the belt.

Check the belt tension. The belt should be snug and not too loose or too tight. Most modern vehicles have automatic tensioners that maintain the correct belt tension, but it's still a good idea to inspect the tensioner. Look for any signs of damage or wear on the tensioner. If the tensioner is loose or if you notice excessive belt vibration, replace the tensioner along with the belt. Finally, check the pulleys for any signs of damage or wear. Make sure the pulleys are clean and free from oil or other contaminants. By following these simple steps, you can regularly inspect your serpentine belt and catch any potential problems before they lead to a breakdown.

What Happens If a Serpentine Belt Breaks?

A broken serpentine belt can have serious consequences for your vehicle's operation. The serpentine belt drives several essential accessories, including the alternator, power steering pump, air conditioning compressor, and water pump. When the belt breaks, these components stop functioning, leading to a cascade of problems.

First, the alternator will stop charging the battery. This will cause the battery to drain quickly, and eventually, the car will stall. You'll likely see a battery warning light on the dashboard before this happens. Second, the power steering will stop working. This will make the car very difficult to steer, especially at low speeds. You'll need to use a lot more force to turn the wheel, which can be dangerous. Third, the air conditioning will stop working. This can be uncomfortable, especially in hot weather.

Fourth, the water pump may stop working. This can cause the engine to overheat quickly, which can lead to serious engine damage. You'll likely see a temperature warning light on the dashboard. If the engine overheats, pull over to the side of the road and let it cool down before attempting to drive again. A broken serpentine belt can also damage other components. The broken belt can wrap around other pulleys and cause them to break or become misaligned. This can lead to even more costly repairs. In short, a broken serpentine belt can leave you stranded and potentially damage your vehicle. That's why it's important to maintain your serpentine belt and replace it at recommended intervals.

Listicle: 5 Signs Your Serpentine Belt Needs Replacing

Knowing when to replace your serpentine belt is crucial for preventing breakdowns and costly repairs. Here's a list of 5 signs that indicate your serpentine belt needs replacing:

- Squealing or Chirping Noises: This is the most common symptom of a worn or loose serpentine belt. The noise is usually caused by the belt slipping on the pulleys.

- Visible Cracks or Fraying: Inspect the belt for any cracks, fraying, or missing chunks. These are all signs of wear and indicate that the belt is about to fail.

- Weakened Power Steering: If your power steering becomes noticeably weaker, especially at low speeds, it could be due to a slipping serpentine belt.

- Non-Cooling Air Conditioner: A slipping serpentine belt can also cause the air conditioning to stop working. If your AC is blowing warm air, check the belt.

- Battery Warning Light: A battery warning light on the dashboard can indicate that the alternator is not charging the battery properly, which could be due to a slipping or broken serpentine belt.

If you notice any of these signs, it's time to replace your serpentine belt. Don't wait until the belt breaks and leaves you stranded on the side of the road. Replacing the belt is a relatively inexpensive and straightforward repair that can save you a lot of headaches in the long run.

Question and Answer

Let's address some common questions about serpentine belts:

Q: How often should I replace my serpentine belt?

A: Most manufacturers recommend replacing the serpentine belt every 60,000 to 100,000 miles. However, this can vary depending on the vehicle and driving conditions. It's always best to consult your vehicle's owner's manual for the recommended replacement interval.

Q: Can I drive with a squealing serpentine belt?

A: While you can technically drive with a squealing serpentine belt, it's not recommended. The squealing noise indicates that the belt is slipping, which can lead to reduced performance of the accessories and eventually a complete belt failure. It's best to address the problem as soon as possible.

Q: How much does it cost to replace a serpentine belt?

A: The cost of replacing a serpentine belt can vary depending on the vehicle and the labor rates in your area. Generally, you can expect to pay between $100 and $200 for a serpentine belt replacement, including parts and labor. Replacing the belt yourself can save you money on labor costs.

Q: What tools do I need to replace a serpentine belt?

A: To replace a serpentine belt, you'll need a socket set, a wrench, a belt routing diagram, and possibly a serpentine belt tool to release the tension on the belt. It's also a good idea to have a flashlight and gloves.

Conclusion of Bad or Loose Serpentine Belt: Symptoms and Replacement

In conclusion, understanding the symptoms of a bad or loose serpentine belt, its function, and the replacement process is crucial for maintaining your vehicle's reliability and preventing unexpected breakdowns. Regular inspections, timely replacements, and proper maintenance are key to extending the life of your serpentine belt and ensuring the smooth operation of your car. Don't ignore unusual noises or changes in performance, and always consult a qualified mechanic if you're unsure about any aspect of serpentine belt maintenance.