Ever felt like your car's engine is talking back to you, but not in a good way? Maybe it's hesitating, lacking power, or making strange noises. These unsettling changes in your vehicle's behavior can be frustrating, leaving you wondering what's wrong and how much it's going to cost to fix.

When your car isn't performing as expected, it's more than just an inconvenience. It can disrupt your daily routine, impact your fuel efficiency, and even lead to costly repairs down the line. Ignoring these warning signs can potentially transform a minor issue into a significant problem, leaving you stranded or facing major engine damage.

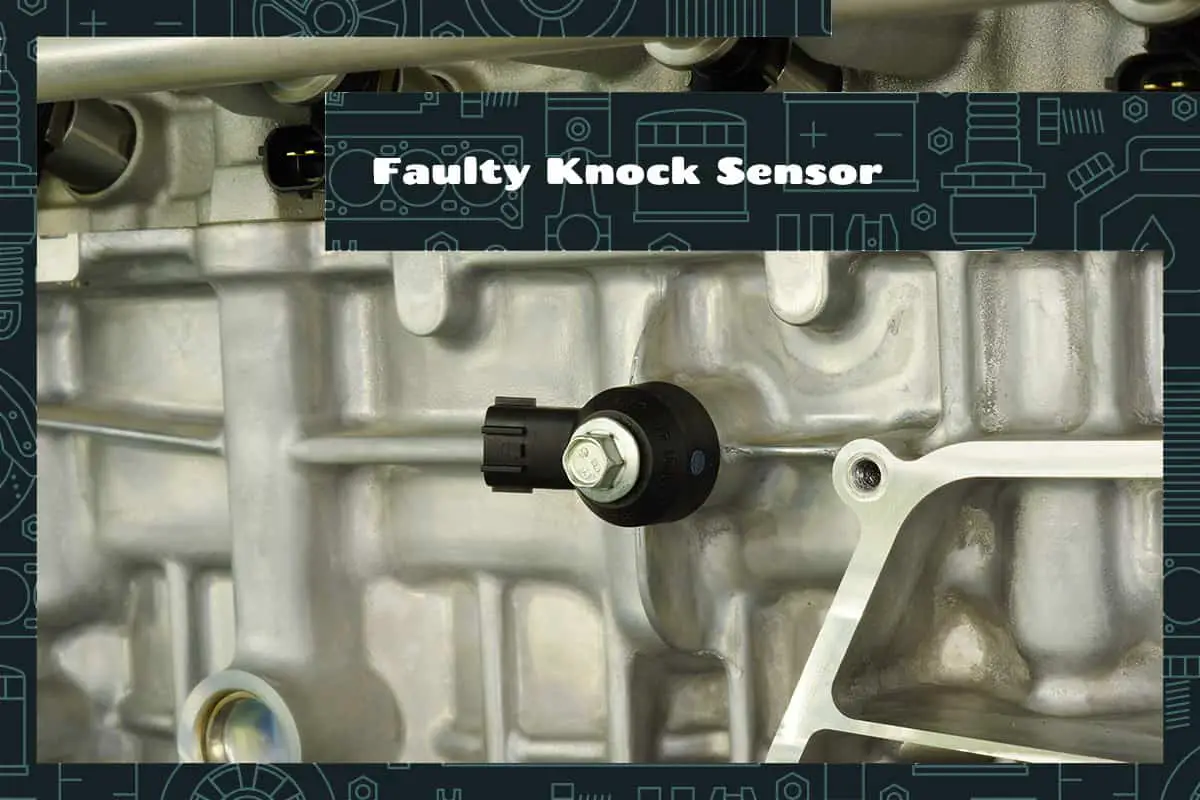

This article dives into the world of knock sensors – those unsung heroes that protect your engine from harmful detonation. We'll explore the symptoms of a faulty knock sensor, how it impacts your car's performance, and what steps you can take to diagnose and address the issue. Understanding these vital components can help you keep your vehicle running smoothly and avoid expensive repairs.

Understanding the role of a knock sensor and its impact on engine performance is essential for any car owner. From recognizing the telltale signs of a failing sensor – such as reduced power, poor fuel economy, and a persistent check engine light – to understanding how a faulty sensor can trigger engine knocking and potential damage, this knowledge empowers you to take proactive steps in maintaining your vehicle's health. We will also discuss troubleshooting, myths, hidden secrets, recommendations, FAQs and more.

My Personal Experience with a Faulty Knock Sensor

I remember one sweltering summer day, my trusty old pickup truck started acting strangely. It had always been a reliable workhorse, but suddenly it felt sluggish, especially when going up hills. The "check engine" light illuminated on the dashboard, adding to my concern. I initially dismissed it as just needing a tune-up, but the problem persisted and even worsened. The engine seemed to hesitate, and I could swear I heard some unusual rattling noises when accelerating. I took it to my local mechanic, a grizzled veteran who knew his way around engines. After a thorough inspection, he delivered the verdict: a faulty knock sensor.

He explained that the knock sensor wasn't doing its job, failing to detect engine knock, also known as detonation. Detonation is a damaging condition where the air-fuel mixture in the cylinders ignites unevenly, causing pressure waves that can physically damage the pistons and cylinder walls. To protect the engine, the car's computer was pulling back timing, resulting in reduced power and poor fuel economy. He replaced the knock sensor, and it was amazing how much better the engine ran! The hesitation was gone, the power returned, and the check engine light vanished. It was like getting my old truck back, and I was grateful for the simple fix that prevented potentially serious engine damage. This taught me the importance of understanding these small, but vital, sensors and how they can significantly impact a vehicle's performance and longevity. Knock sensors are often located in the engine block or cylinder head, so proper diagnostic tools are needed to correctly assess a vehicle. Sometimes the sensors are difficult to reach, and it is much easier to let the professional handle the work.

Understanding the Knock Sensor's Role

The knock sensor is a small, yet critical, component in modern internal combustion engines. Its primary function is to detect engine knock, or detonation, which occurs when the air-fuel mixture in the cylinders ignites in an uncontrolled and uneven manner. This abnormal combustion creates pressure waves that can damage pistons, connecting rods, and cylinder heads. Think of it as the engine's early warning system, protecting it from potentially catastrophic damage.

The knock sensor works using a piezoelectric element. This element generates a small electrical voltage when subjected to vibration, which is caused by engine knock. The sensor transmits this voltage signal to the engine control unit (ECU), also known as the car's computer. If the ECU detects a signal indicating knock, it will retard, or reduce, the ignition timing. This change in timing reduces the cylinder pressure and prevents detonation. By constantly monitoring and adjusting the timing, the knock sensor allows the engine to run at its maximum potential while protecting it from damage. In some engines, the use of high-octane fuel is needed to prevent engine knocking, and to help the knock sensor to continue to do its work. The proper torque of a knock sensor is also very important, as torque too low or too high could result in inaccurate readings. Also, a broken wire harness going to the knock sensor could prevent the sensor from operating correctly.

Myths and History of Knock Sensors

While the modern knock sensor seems like a high-tech marvel, the concept of detecting and mitigating engine knock has been around for much longer than you might think. Early attempts to address engine knock focused on mechanical solutions, such as adjusting ignition timing manually based on engine noise. However, these methods were imprecise and often ineffective. The development of electronic knock sensors in the late 20th century marked a significant advancement, allowing for real-time monitoring and adjustment of ignition timing.

One common myth is that a faulty knock sensor automatically means your engine is doomed. While ignoring a bad knock sensor can lead to serious damage, addressing it promptly can prevent major problems. Another myth is that you can simply disconnect the knock sensor to bypass the issue. While this might seem like a quick fix, it can lead to significantly reduced engine performance and increased risk of engine damage. Some people also believe that using high-octane fuel eliminates the need for a functioning knock sensor. While high-octane fuel can reduce the likelihood of knock, it doesn't eliminate the need for the sensor, especially in engines designed to run on regular fuel. The knock sensor is a vital component in modern engines, and understanding its history and function is essential for proper maintenance and preventing costly repairs. By debunking these myths, we can gain a better understanding of the knock sensor's true role and importance in engine management. The fuel octane rating is defined as the percentage of iso-octane in the gasoline. For example, if the fuel has an octane rating of 91, it means there is 91% iso-octane in the gasoline.

Hidden Secrets of Knock Sensors

Beyond their basic function of detecting engine knock, knock sensors hold a few hidden secrets that can be useful for understanding their behavior and troubleshooting issues. For example, did you know that some advanced engine management systems use multiple knock sensors to pinpoint the exact cylinder where knock is occurring? This allows for more precise adjustments to ignition timing, maximizing performance and efficiency. Another secret is that the sensitivity of a knock sensor can degrade over time due to heat, vibration, and contamination. This degradation can lead to inaccurate readings, potentially causing the ECU to retard timing unnecessarily or, conversely, failing to detect knock when it's actually present.

Furthermore, the location of the knock sensor on the engine block can have a significant impact on its performance. Sensors placed closer to the cylinders are generally more sensitive to knock, while those located farther away may be less accurate. Understanding these hidden aspects of knock sensors can help you diagnose issues more effectively. For instance, if you're experiencing persistent engine hesitation or poor fuel economy despite a functioning knock sensor, it might be worth investigating the sensor's sensitivity or its location on the engine. These small details can make a big difference in getting the most out of your vehicle and protecting its engine from damage. Also, some aftermarket performance modifications require adjusting the sensitivity range to allow the engine to make more horsepower. However, this should only be performed by a highly-skilled professional.

Recommendations for Knock Sensor Issues

If you suspect you have a faulty knock sensor, there are a few recommendations to keep in mind. First, don't ignore the symptoms. Reduced power, poor fuel economy, and a persistent check engine light are all warning signs that something is amiss. Ignoring these signs can lead to more serious engine damage. Second, get a proper diagnosis. Don't simply assume the knock sensor is the problem without confirming it with a diagnostic scan. A mechanic can use a scan tool to read the diagnostic trouble codes (DTCs) and determine if the knock sensor is indeed the culprit.

Third, use quality replacement parts. When replacing a knock sensor, it's essential to use a high-quality part from a reputable manufacturer. Cheap aftermarket sensors may not be as accurate or durable, potentially leading to future problems. Finally, consider having a professional install the new sensor. While replacing a knock sensor might seem like a straightforward task, it often requires specialized tools and knowledge. Improper installation can damage the sensor or the engine. By following these recommendations, you can ensure that your knock sensor issues are addressed effectively, protecting your engine and maintaining your vehicle's performance. The knock sensor's wiring harness should also be inspected for any damage, corrosion, or loose connections. Also, it is important to clean all mating surfaces of the engine before installing the new sensor.

Symptoms of a Faulty Knock Sensor

A faulty knock sensor can manifest in several ways, each affecting your vehicle's performance differently. One of the most common symptoms is reduced engine power. The ECU, sensing a potential knock, may retard the ignition timing, which reduces the engine's output. You might notice this as sluggish acceleration or difficulty climbing hills. Another symptom is poor fuel economy. When the ECU retards the timing, the engine becomes less efficient, resulting in lower MPG. The check engine light is a classic sign of a problem. While it can indicate a variety of issues, a faulty knock sensor will often trigger this light, storing a diagnostic trouble code related to the sensor.

Additionally, you might experience rough idling or engine hesitation. The ECU's attempts to compensate for the perceived knock can cause the engine to run unevenly, especially at idle. In some cases, you might even hear actual engine knocking or pinging, although this is less common. These symptoms can be subtle or pronounced, depending on the severity of the knock sensor failure. It's important to pay attention to any changes in your vehicle's performance and seek professional diagnosis if you suspect a problem. A good place to start is with an OBD II scan tool, which could help narrow down the problem. Also, the fault codes of the check engine light will point directly to the knock sensor.

Tips for Maintaining Your Knock Sensor

While knock sensors are generally reliable, there are a few things you can do to maintain them and prevent premature failure. First, use the correct fuel grade for your vehicle. Consult your owner's manual for the recommended octane rating and avoid using lower-grade fuel, which can increase the risk of engine knock. Second, keep your engine well-maintained. Regular oil changes, spark plug replacements, and other maintenance tasks can help prevent engine problems that could stress the knock sensor.

Third, avoid harsh driving habits. Excessive acceleration, high-speed driving, and overloading your vehicle can increase the likelihood of engine knock. Finally, be mindful of any changes in your vehicle's performance. If you notice any of the symptoms of a faulty knock sensor, such as reduced power or poor fuel economy, have your vehicle inspected promptly. By following these tips, you can help prolong the life of your knock sensor and keep your engine running smoothly. Also, refrain from using harsh engine cleaners. The chemicals from harsh engine cleaners could cause damage to the knock sensor.

Diagnosing a Knock Sensor Issue

Diagnosing a knock sensor issue typically involves a combination of visual inspection and diagnostic testing. Start by visually inspecting the sensor and its wiring for any signs of damage, corrosion, or loose connections. Use a multimeter to check the sensor's resistance and voltage output. Compare these readings to the manufacturer's specifications to determine if the sensor is functioning correctly. A diagnostic scan tool is invaluable for diagnosing knock sensor issues.

The scan tool can read the diagnostic trouble codes (DTCs) stored in the ECU, providing valuable information about the nature of the problem. Common DTCs associated with knock sensors include P0325 (Knock Sensor 1 Circuit Malfunction) and P0330 (Knock Sensor 2 Circuit Malfunction). The scan tool can also be used to monitor the knock sensor's output in real-time, allowing you to observe its response to engine conditions. In some cases, you may need to perform additional tests, such as a wiring continuity test, to rule out any problems with the sensor's wiring harness. By following a systematic diagnostic approach, you can accurately identify whether the knock sensor is faulty and take appropriate action.

Fun Facts About Knock Sensors

Did you know that knock sensors are sometimes used in racing applications to provide real-time feedback on engine knock? This allows racers to adjust their driving style and engine settings to maximize performance while minimizing the risk of engine damage. Another fun fact is that some knock sensors are designed to "learn" the engine's normal vibration patterns. This allows them to distinguish between normal engine noise and actual engine knock, improving their accuracy. Knock sensors are also used in other applications besides automobiles. They can be found in generators, marine engines, and even some industrial equipment.

The design and function of knock sensors have evolved significantly over the years. Early knock sensors were relatively simple devices, while modern sensors are more sophisticated, incorporating advanced signal processing techniques. Some high-performance engines even use multiple knock sensors, strategically placed around the engine block to provide more comprehensive knock detection. These fun facts highlight the versatility and importance of knock sensors in various applications and the ongoing efforts to improve their performance and reliability. In some engines, the engine knock is artificially induced by the manufacturer as a way to increase engine compression, and thus fuel economy.

How to Replace a Faulty Knock Sensor

Replacing a faulty knock sensor is a task that can be done by a skilled DIY mechanic, but it's important to proceed with caution and follow the proper steps. First, gather the necessary tools and materials, including a new knock sensor, socket set, torque wrench, and possibly a repair manual specific to your vehicle. Disconnect the negative battery cable to prevent any electrical accidents. Locate the knock sensor on the engine block. Its location can vary depending on the make and model of your vehicle, so consult a repair manual or online resources if needed. Disconnect the electrical connector from the knock sensor. Use a socket wrench to remove the old knock sensor from the engine block. Be careful not to damage the surrounding components.

Install the new knock sensor, tightening it to the manufacturer's specified torque using a torque wrench. Over-tightening or under-tightening the sensor can affect its performance. Reconnect the electrical connector to the knock sensor. Reconnect the negative battery cable. Start the engine and check for any error codes or unusual noises. If everything seems normal, take your vehicle for a test drive to ensure that the new knock sensor is functioning correctly. If you're not comfortable performing this task yourself, it's best to have a qualified mechanic replace the knock sensor. This will ensure that the job is done correctly and prevent any potential damage to your vehicle. Before installing the new sensor, apply a small amount of anti-seize compound to the threads of the new sensor.

What if You Ignore a Faulty Knock Sensor?

Ignoring a faulty knock sensor can have serious consequences for your engine. The primary function of the knock sensor is to protect the engine from detonation, a damaging condition that can cause significant wear and tear on engine components. When the knock sensor fails, the engine is more susceptible to detonation, especially under heavy load or high-stress conditions. Over time, this can lead to damaged pistons, connecting rods, and cylinder heads, resulting in costly repairs or even engine failure. Furthermore, a faulty knock sensor can cause the engine control unit (ECU) to retard the ignition timing, which reduces engine power and fuel economy. This can make your vehicle feel sluggish and less responsive, and it can also increase your fuel costs. In some cases, a faulty knock sensor can also cause the engine to run rough or stall, making your vehicle unreliable and unsafe.

Therefore, it's essential to address any knock sensor issues promptly. If you suspect that your knock sensor is faulty, have your vehicle inspected by a qualified mechanic and replace the sensor if necessary. By taking proactive steps, you can protect your engine from serious damage and maintain your vehicle's performance and fuel efficiency. Also, engine knocking can cause pre-mature wear on the piston rings, cylinder walls, and connecting rod bearings.

Listicle of Knock Sensor Benefits

Here's a listicle outlining the benefits of a properly functioning knock sensor:

- Protects Your Engine: Prevents damaging engine knock and detonation.

- Maintains Performance: Allows the engine to run at its optimal timing for maximum power.

- Improves Fuel Economy: Ensures efficient combustion, leading to better MPG.

- Reduces Emissions: Helps maintain optimal combustion, reducing harmful emissions.

- Prevents Costly Repairs: Avoids potential engine damage, saving you money in the long run.

- Ensures Smooth Operation: Keeps the engine running smoothly and reliably.

- Extends Engine Life: Protects engine components, prolonging the life of your engine.

- Provides Peace of Mind: Knowing your engine is protected from damage.

- Optimizes Ignition Timing: Adjusts timing to maximize efficiency and power.

- Detects Abnormal Combustion: Monitors for signs of engine knock and responds accordingly.

These benefits highlight the importance of maintaining a properly functioning knock sensor in your vehicle. By understanding these advantages, you can appreciate the value of this small, yet vital, component.

Question and Answer about Faulty Knock Sensor

Question 1: What are the most common symptoms of a faulty knock sensor?

Answer: Reduced engine power, poor fuel economy, a persistent check engine light, rough idling, and engine hesitation are all common symptoms. In some cases, you might also hear actual engine knocking or pinging.

Question 2: Can a faulty knock sensor cause serious engine damage?

Answer: Yes, if left unaddressed, a faulty knock sensor can lead to engine knock, which can damage pistons, connecting rods, and cylinder heads, potentially resulting in costly repairs or engine failure.

Question 3: Is it possible to diagnose a knock sensor issue myself?

Answer: Yes, you can start by visually inspecting the sensor and its wiring for damage. You can also use a multimeter to check the sensor's resistance and voltage output. A diagnostic scan tool can also be used to read any diagnostic trouble codes (DTCs) related to the knock sensor.

Question 4: How often should I replace my knock sensor?

Answer: There's no specific replacement interval for knock sensors. However, it's recommended to inspect them periodically and replace them if they show any signs of damage or malfunction.

Conclusion of Faulty Knock Sensor

The knock sensor is a critical component in modern engines, protecting them from damaging detonation and ensuring optimal performance. Recognizing the symptoms of a faulty knock sensor, understanding its function, and taking proactive steps to address any issues are essential for maintaining your vehicle's health and longevity. By following the tips and recommendations outlined in this article, you can keep your engine running smoothly and avoid costly repairs down the line. A properly functioning knock sensor is an investment in your vehicle's reliability and performance, providing peace of mind and ensuring a safe and enjoyable driving experience.